Charcoal Making Machine Manufacturer

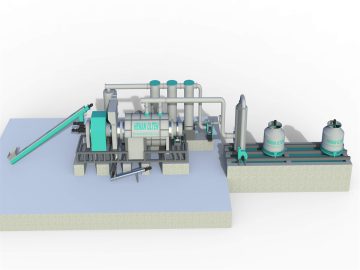

Continuous Biomass Pyrolysis Machine

Continuous biomass pyrolysis machine truly realizes the multi-purpose of one machine, which can be used to pyrolysis carbonize biomass such as sawdust, coconut shell, bamboo chips, straw, etc., as well as pyrolysis carbonize sludge, domestic waste and electronic waste etc.

Continuous Carbonization Machine

Continuous carbonization machine truly realizes the multi-purpose of one machine, which can be used to carbonize biomass such as sawdust, coconut shell, bamboo chips, straw, etc., as well as carbonize sludge, domestic waste and electronic waste, etc. The whole process is smoke-free and pollution-free.

Continuous Carbonization Furnace

Continuous carbonization machine is widely used in various fields of charcoal processing and production.It is one of the important equipment for charcoal making production.

OLT-P273 Continuous Carbonization Machine

OLT-P273 continuous carbonization machine , integrated frame design, installation-free and removable.

Horizontal Carbonization Furnace

Horizontal carbonization furnace is an environmentally friendly and smokeless carbonization equipment.It is one of the important equipment for charcoal making production.

Hoisting Carbonization Furnace

Hoisting carbonization furnace is widely used in various fields of charcoal processing and production.It is an environmentally friendly and smokeless carbonization equipment and is one of the important equipment for charcoal making production.

Wheel Mill Mixer

Wheel mill mixer is widely used in carbon powder molding, coal powder molding, non-burning bricks, autoclaved bricks, refractory materials, ceramics, building materials and other industries.

Charcoal Ball Briquette Machine

Charcoal ball briquette machine is one of the main equipment for charcoal briquette , can device presses powdery and granular materials into molding.

Charcoal Stick Briquette Machine

Charcoal stick briquette machine is one of the main equipment for charcoal briquette ,can be charcoal powder, carbon residue, bamboo charcoal, coconut husk charcoal, rice husk charcoal and other raw materials can be extruded.

Wood Charcoal Briquette Machine

Wood charcoal briquette machine is one of the main equipment for charcoal briquette, which mainly passes qualified sawdust and wood materials or biomass materials (under 5mm in size, 12% moisture) through spirals, high pressure forming cylinders and heating rings.

Rotary Drum Dryer

Rotary Drum Dryer is one of the main equipments in the drying process in the charcoal making production process. The equipment is reliable in operation, flexible in operation, strong in adaptability, and large in processing capacity.

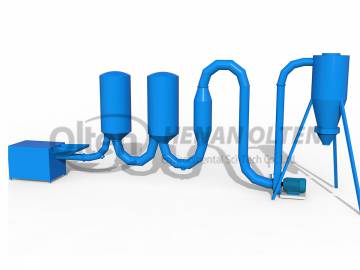

Air Dryer

Air dryer is is one of the main equipments in the drying process in the charcoal making production process, with direct heating, fast drying, foldable installation, and space saving.

COMPANY PROFILE

Henan Olten Environmental Sci-Tech Co., Ltd. is a comprehensive enterprise focusing on the research and development and sales of charcoal making machine equipment . The factory was established in 1989 and is located in Gongyi City, Henan Province.

OUR CASES

The Difference Between Charcoal Burning In Earth Kiln And Charcoal Furnace

Use the carbonization furnace to burn charcoal, and the operation according to the temperature display is simple and convenient.

Introduction Of Carbonization Furnace About Carbonization Time

The time of material carbonization is mainly distributed in the dehumidification stage, thermal decomposition stage, carbonization stage, and cooling stage. Among them, the longest time is the dehumidification stage and the cooling stage.

What Is The Difference Between Machine-Made Charcoal, Charcoal And Type Charcoal?

Machine-Made Charcoal, Charcoal And Type Charcoal,comparative analysis of advantages and disadvantages

the Best Sea and Air Freight Services

For Book Your Shipping From any Country Contact With Us0

Project Done

0

Permanent Clients

0

Owned Vehicles

0

Support Member

LATEST NEWS

Carbonization – solving the problem of municipal solid waste

2022-10-21Carbonization is a kind of pyrolysis technology of biomass under anoxic or oxygen poor conditions to prepare corresponding carbon materials.

Analysis on the usages of biochar produced by Olten® charcoal making machine

2022-10-19Biochar is a kind of biochar that has been "processed" by high temperature pyrolysis. The pyrolysis process not only produces stable carbon form - charcoal, but also produces by-products such as syngas and liquid tar. Both of these by-products can be used as fuel for power generation or heating.

Analysis and introduction of biomass carbonization process

2022-10-18According to the research of solid fuel combustion theory and biomass solution dynamics, the biomass carbonization process can be divided into the following stages: