Product introduction

OLT-P273 continuous carbonization machine takes sawdust, rice husks, coconut shells, etc. and various biomass materials, and the biomass materials that have been crushed (size less than 10mm) and dried (moisture content less than 15%) are put into the carbonization machine for high-temperature digestion. Aerobic anaerobic pyrolysis treatment is a continuous carbonization equipment.

Working principle

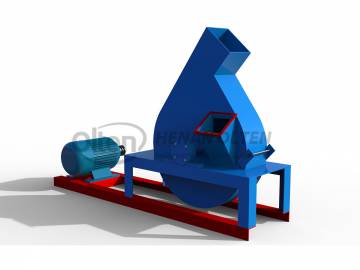

① Preheating is carried out in the early stage. The heat source can be wood, coal, natural gas, liquefied gas, etc. Unique combustion chamber design, the host uses hot air heating when the equipment is preheated to 300℃-350℃. Try cutting for the first time.

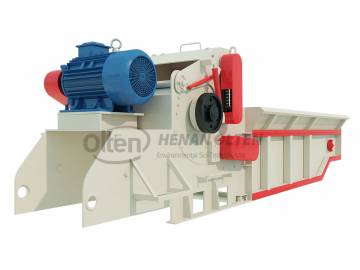

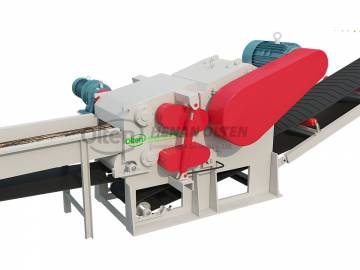

②The feeding machine will enter the materials that meet the feeding requirements into the pipe of the carbonization machine. The main machine feeding port adopts an air-closer design to achieve uniform discharging and sealing.

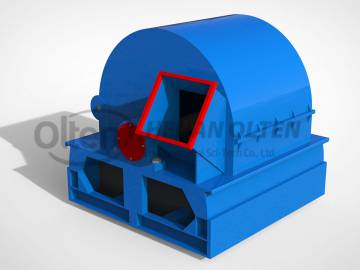

③The carbonization pipeline adopts a “z” shape distribution, and the discharge port is designed with a baffle plate to prevent the material from being drawn out, causing blockage of the pipeline and material leakage.

④The flue gas during the carbonization process is extracted through a stainless steel induced draft fan, processed by the flue gas purification system, and returned to the combustion chamber for full combustion and waste heat utilization. The waste heat after high-temperature incineration can also be used in dryers.

⑤The carbonized material is cooled and transported for cooling treatment.

Product Advantages

-

-

-

-

-

-

- (1)The feed inlet of the main machine adopts an air-closed design, which allows for uniform feeding and good sealing to prevent air from entering during the production process and during shutdown, causing internal natural deflagration.

- (2)The carbonization pipes of the main machine are arranged in a “Z” shape, with a long stroke and good carbonization effect; the discharge port of each pipe is designed with a baffle plate to prevent dust from being extracted during the carbonization process, causing pipe blockage and material leakage.

- (3)Unique combustion chamber design can adapt to a variety of heating methods, and different heating methods can be selected according to the actual production needs of customers.

- (4)The treated flue gas enters the combustion chamber through the induced draft fan and is burned at high temperature, which has the effect of waste heat utilization and purification treatment.

-

-

-

-

-