Product Introduction

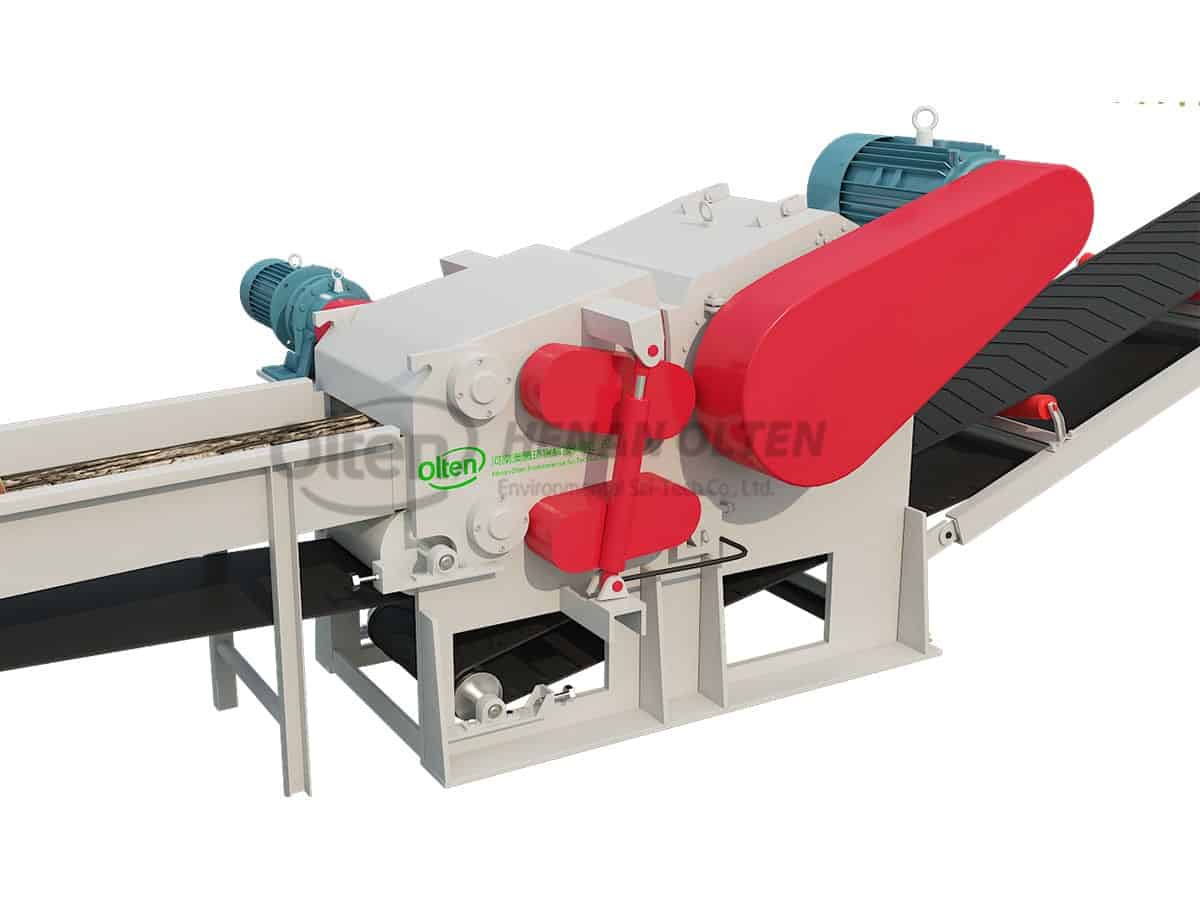

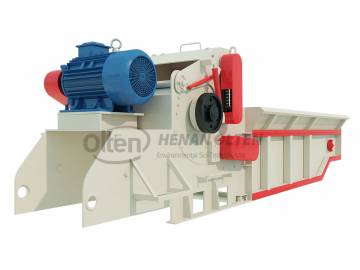

Drum chipper is one of the main equipments in the crushing raw mateials in the charcoal making production process, which is used in the wood chip production and export bases of paper mills, particleboard mills, and fiberboard mills.

Drum chipper can cut logs and small-diameter wood into high-quality industrial wood chips with uniform length, flat cuts and uniform thickness.It can also cut branches and boards.

drum chipper

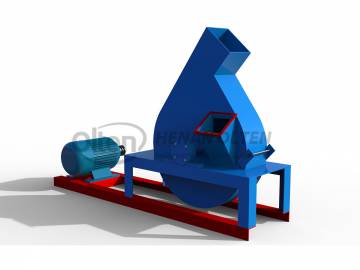

Working Principle

When the drum chipper is working, the material is conveyed to the crushing bin through the conveyor, and the rotor with blades is used to slice the wood through the principle of cutting wood. The size of the finished product is controlled by the size of the screen aperture, the number of blades, the cutter and the bottom knife .

Core Components

- Knife: high-speed alloy steel.

- Knife roll: manganese steel castings are integrally formed, quenched and tempered, and have strong durability.

- Motor: well-known domestic brand.

Product Advantages

- (1)Wide application range, wide use, small area, good output (wood chips) finished product.

- (2)The rotor rotates at high speed to cut the material. Bottom knife assist, secondary cutting. Make the wood chips more regular.

- (3)The hydraulic device of the upper feeding roller makes the feeding more stable and smooth.

- (4)Compared with the disc chipper, the output is larger and the efficiency is higher.

Product Parameter

| Model | BX215 | BX216 | BX218 |

| Diameter of knife roller (mm) | 500*460 | 650*600 | 800*780 |

| Inlet size (mm) | 430*170 | 540*240 | 700*310 |

| Feeding speed (m/min) | 36 | 36 | 38 |

| Wood chip length (mm) | 25-35 | 30-35 | 25-35 |

| Processing capacity (t/h) | 3-5 | 5-12 | 8-18 |

| Power (kw) | 37 | 55 | 110 |

| Weight (t) | 3.2 | 4.3 | 7 |

| Dimensions (mm) | 1540*1240*1420 | 2000*1900*1650 | 2670*2150*1900 |