Product Introduction

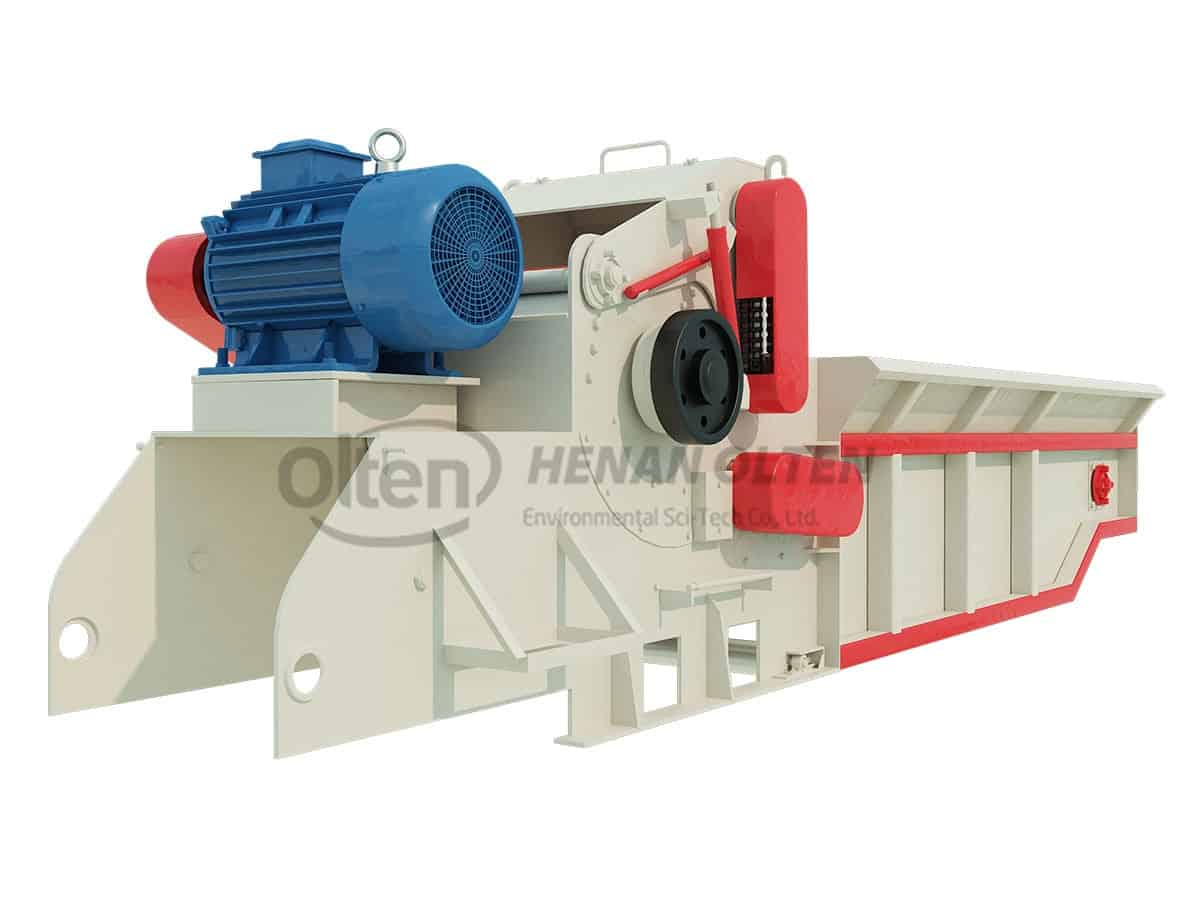

Integrated crusher is one of the main equipments in the crushing raw mateials in the charcoal making production process.

Integrated crusher is a large-scale wood crushing equipment for crushing branches, tree roots, templates, wooden pallets, waste furniture, nailed wood and other materials.

Integrated crusher is suitable for particle board factories, medium and high density fiberboard factories, biomass power plants, wood chip factories, power plants, boiler plants, etc.

integrated crusher

Working Principle

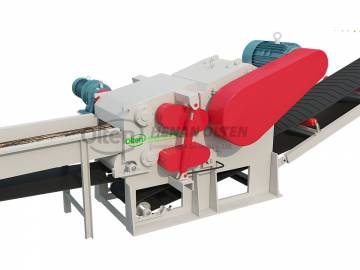

When the biomass wood integrated crusher is working, the material is transported to the crushing bin through the chain conveyor, and the wood is crushed by the principle of hammer (or blade) hitting the wood.

The size of the finished product is controlled by the size of the screen aperture, and at the end of the discharge conveying Equipped with high magnetic magnetic roller, biomass wood integrated crusher can achieve 100% nail removal.

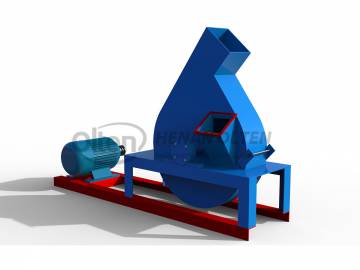

Core Components

- Rotor and main shaft: alloy castings are quenched and tempered, and have been checked and balanced.

- Knife: high-speed alloy die steel, high hardness, no edge curling, durable.

- Hammer head: cast steel parts sprayed with tungsten carbide alloy, high hardness, wear resistance, and good crushing effect.

- Screen: thick manganese plate, high hardness, impact resistance.

Product Advantages

- (1)The speed of the knife roller is adjustable, and the rotor can be replaced according to the customer’s material, using a knife or hammer.

- (2)Hydraulic forced feeding, the machine has a wider adaptability to raw materials, and the feeding is more stable and smooth.

- (3)Hydraulic system, frequency conversion adjustment, safe and simple operation, convenient maintenance.

- (4)The chain plate conveys and feeds more smoothly; the chain plate is made of high manganese steel with a thickness of 10mm, which is more wear-resistant and has a long service life.

- (5)Overload power-off protection, when overloading, it will automatically cut off the circuit.

- (6)For building templates and wooden pallets, a magnetic separation device is installed to effectively remove metal impurities.

Product Parameter

| Model | Power( kw ) | Feed size( mm ) | Weight( t ) | Processing Capacity( t/h ) |

| 600 | 37 | 160*600 | 5 | 3-4 |

| 900 | 45 | 220*900 | 6 | 4-6 |

| 1100 | 55 | 330*1100 | 7 | 5-7 |

| 1300 | 90-110 | 400*1300 | 13 | 11-16 |

| 1500 | 132-160 | 500*1500 | 21 | 18-25 |

| 2000 | 315 | 550*2000 | 47 | 30-45 |