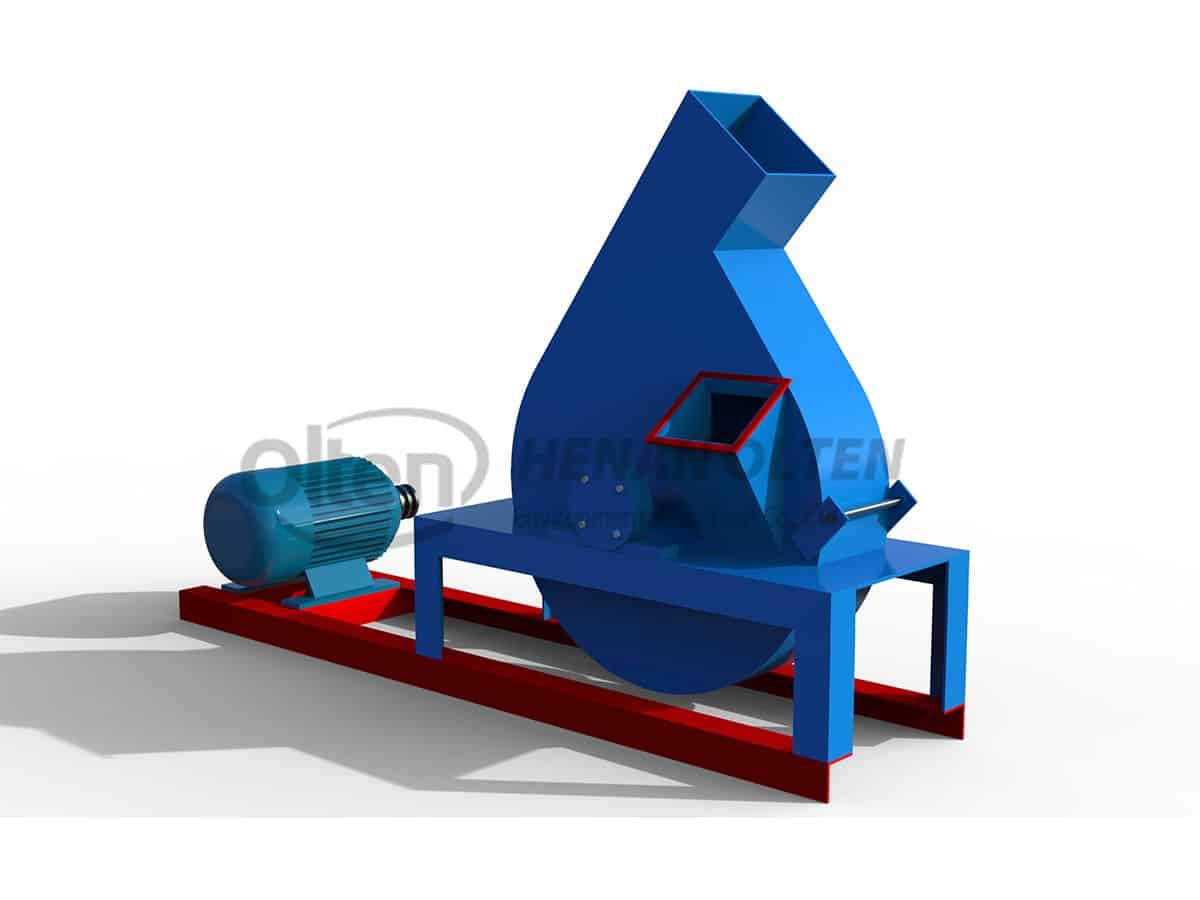

Product Introduction

Disc chipper is one of the main equipments in the crushing raw mateials in the charcoal making production process, which is a special equipment for preparing high-quality wood chips. It can cut logs, small diameter wood, etc. into high-quality industrial wood chips with uniform length, flat cuts and uniform thickness, and can also cut ya wood, boards, etc. It is suitable for paper mills, particle board mills, fiberboard mills and wood chip production bases.

disc chipper

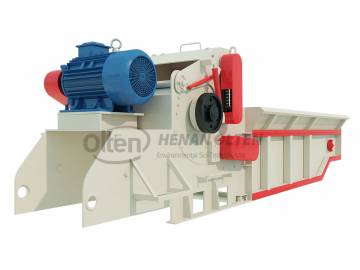

Working Principle

When it is working, the raw material passes through the feed port, passes through the high-speed rotating cutter head rotor inlaid with blades, cuts the material, and discharges the cut product through the discharge port along with the high air pressure. The size and thickness can be controlled by the number and angle of the blades.

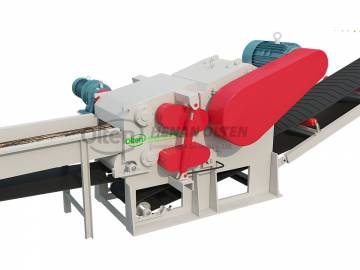

Core Components

- Knife: high-speed alloy steel.

- Knife roll: manganese steel castings are integrally formed, quenched and tempered, and have strong durability.

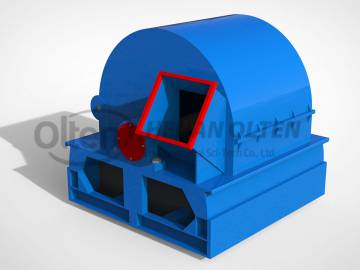

Product Advantages

- (1)Wide application range, low cost, good finished product and high stability.

- (2)Disc chipper can be driven by electric motors, diesel engines and gasoline engines, and can realize mobile operation.

Product Parameter

| Model | 450 | 800 | 1150 | 1410 |

| Power(kw) | 11 | 30 | 55 | 90 |

| Feed Size(mm) | 150*150 | 200*200 | 300*330 | 400*400 |

| Processing capacity(t/h) | 0.6~1 | 3~4 | 6~8 | 10~12 |