Product introduction

Continuous carbonization furnace, also known as continuous carbonization machine, is widely used in various fields of biochar processing and production. It converts various biomass into biochar through rapid carbonization technology and is an important biochar production equipment.

Continuous carbonization furnace is a new type of carbon powder carbonization machine that feeds in the raw materials and discharges the finished carbon. It is an external heating type drying and carbonization conjoined machine. The entire production process does not produce harmful gases, no smoke emissions, and the generated smoke is self-contained Use, do not pollute the environment.

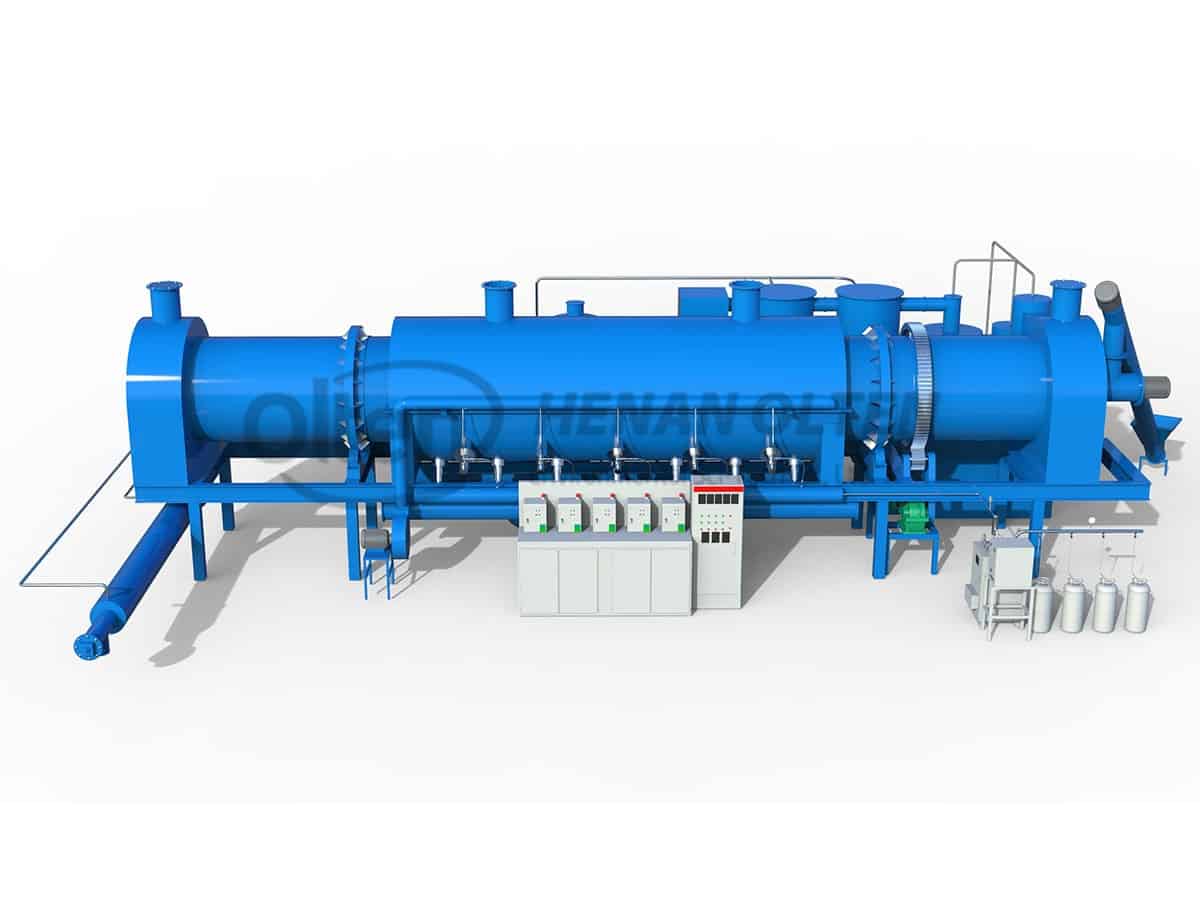

continuous carbonization furnace

Working principle

When the continuous carbonization furnace is working, the sawdust, rice husk, coconut husk, etc. and various biomass raw materials (size less than 30mm, moisture less than 15%) that need to be carbonized (size less than 30mm, moisture less than 15%) are heated to 300°C through a gasification furnace or a fire box. The feeding screw is conveyed and sent into the carbonization drum through the screw propeller. Dehumidification, decomposition and carbonization are carried out in a high temperature (heating temperature can reach 600°C) and an oxygen-free environment.

The flue gas and combustible gas produced in this process are uniformly processed by the flue gas purification and recovery device to achieve smokeless emission; after the combustible gas is collected, it will flow to the bottom of the furnace for recycling and use. In this process, it will form a continuous feed. Material, the effect of continuous carbonization, so as to achieve continuous production.

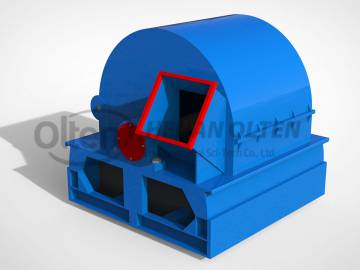

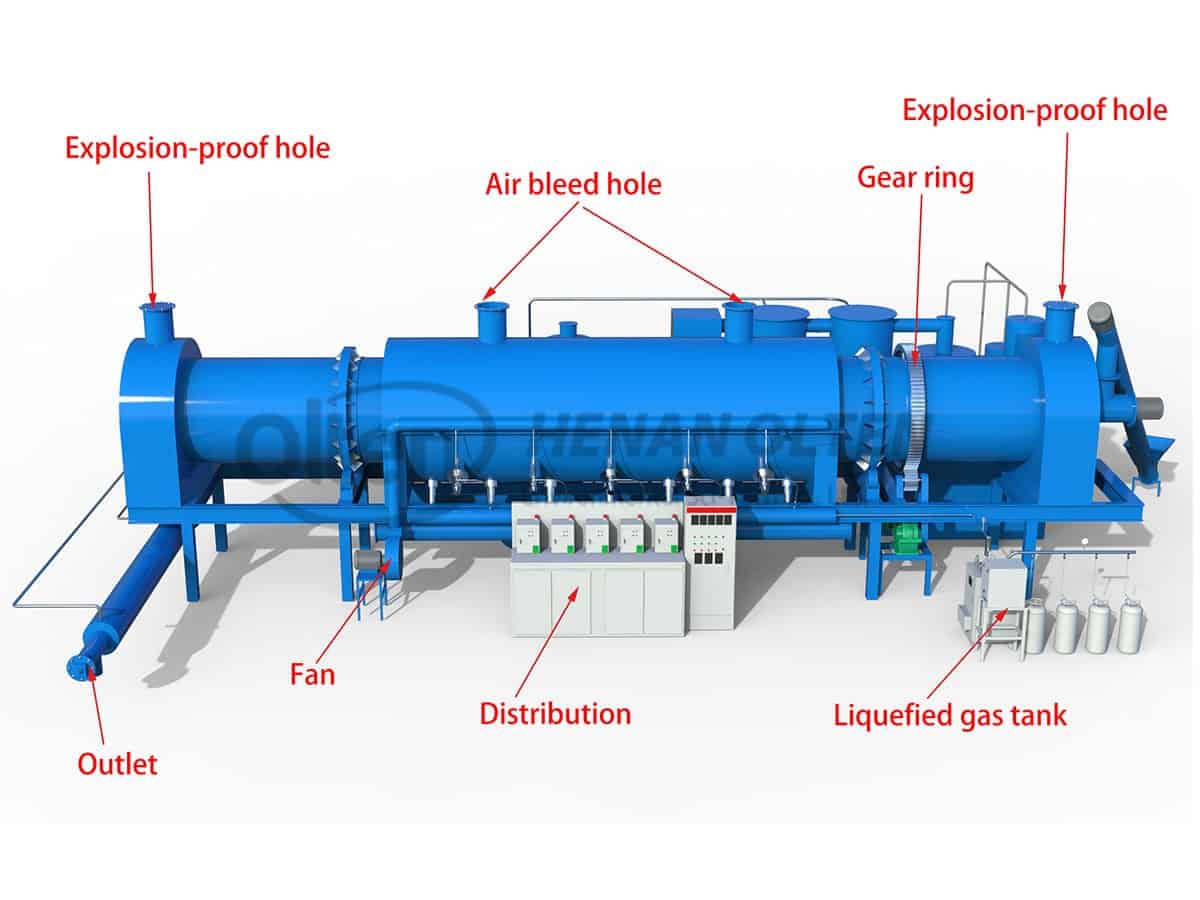

continuous carbonization furnace structure diagram

Core Components

- Rotary drum: boiler steel plate (12mm thick, Q245R), high temperature resistance, good heat preservation.

- Gear ring: It is made of cast steel parts, quenched and forged, with high hardness, good wear resistance and not easy to break.

- Base: adopt national standard B-type thick I-beam, with high strength and good stability.

- Control system: advanced control system, high degree of automation, integrated temperature control, speed control, air leakage alarm and other advantages.

Product Advantages

- Heating method: gas, natural gas, wood, coal, etc. are available for various options. Equipped with one-key ignition, safe and reliable.

- Control system: high degree of automation, temperature controllable, air leakage alarm.

- Flue gas recovery device: It recovers and reuses combustible gases such as carbon monoxide, methane, and oxygen produced during the carbonization process to save fuel.

- Cooling system: Cooling by circulating water and equipped with high-efficiency large-capacity evaporation tower, high efficiency, to ensure the quality of the finished product.

Product Parameter

| Model | Power ( kw ) | Weight( t ) | Processing Capacity ( kg/h ) | Drum Size(m) |

| LXC1000 | 47.35 | 12.5 | 500-600 | 1*10.5 |

| LXC1200 | 47.35 | 13.5 | 600-800 | 1.2*10.5 |

Want to know more about the process of Continuous Biomass Pyrolysis Machine , contact us.